What is a Hydro-Boost Brake System?

A Hydro-Boost brake system is a special type of power brake booster that uses hydraulic brakes instead of engine vacuum. It connects directly to the power steering pump to get pressure. This makes it ideal for vehicles with diesel engines, superchargers, or low engine vacuum. Unlike vacuum systems, the Hydroboost system gives consistent brake pedal pressure under any load.

You often find Hydroboost components in heavy-duty trucks like the Ford F-350 Hydroboost and other Ford Super Duty brakes. These systems help drivers get better brake response time even when towing or carrying heavy loads. The system is compact, strong, and very reliable compared to older designs.

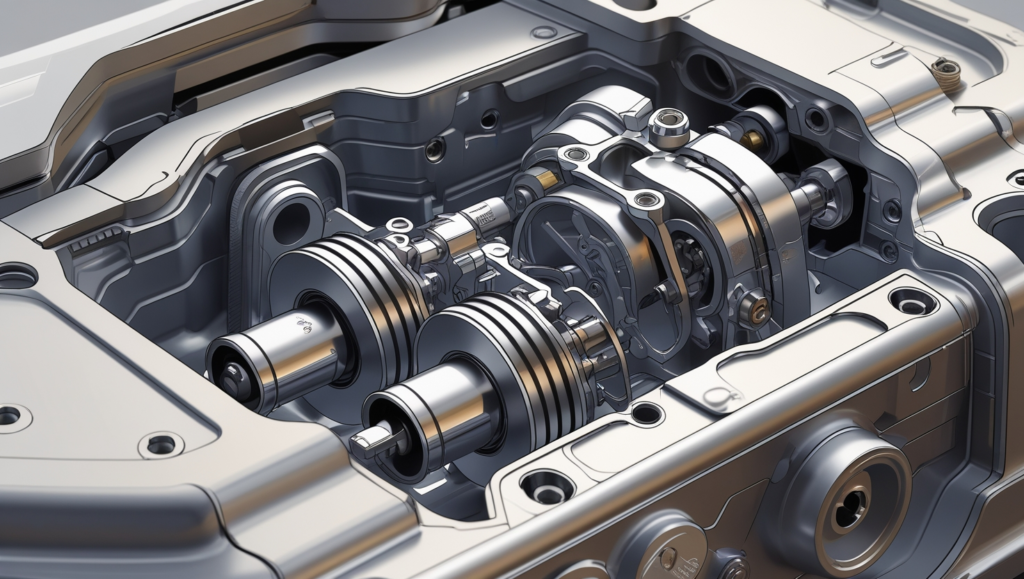

How the Hydro-Boost System Operates

The Hydroboost system works by channeling hydraulic fluid from the power steering pump to the Hydroboost components. This creates strong pressure that pushes the master cylinder forward. That’s how you get strong brake pedal pressure without much effort. If the engine stops, an internal accumulator gives one or two emergency stops using stored pressure.

This system is connected to the steering fluid system, so if there’s a leak or failure, both the steering and braking could be affected. Fluid moves through brake lines and pushes on pistons in the master cylinder, which applies the brakes. With Hydroboost psi running around 1,200–1,500, it delivers power safely and smoothly.

Signs and Symptoms of a Failing Hydro-Boost System

When your Hydroboost performance starts to drop, you may feel a spongy brake pedal or hear odd noises when pressing the brakes. If your vehicle becomes hard to stop or the brake pedal soft and slow to return, it’s a red flag. You might also feel a stiff pedal, especially when turning or braking.

Watch out for brake pressure loss symptoms, which can feel like weak stopping power. Leaking fluid near the Hydroboost components is another sign. If the power steering becomes noisy or stiff, the Hydroboost system might be losing pressure or fluid.

Diagnosing Hydro-Boost System Issues

Start by checking for leaks, especially where the Hydroboost brake system meets the power steering pump or master cylinder. If you hear groaning or hissing, it may be due to fluid aeration or bad seals. Use a pressure gauge for brakes and test through the pressure test port to check for proper Hydroboost pressure.

Look for worn master cylinder seals, dirty fluid, or air in the lines. These can make the brakes feel weak or cause the brake pedal soft. If the Ford braking system doesn’t feel right, check the Hydroboost troubleshooting steps before replacing anything.

How Much Pressure Does a Ford Hydro-Boost Require?

For most Ford trucks, especially Ford Hydroboost units, normal pressure is between 1,200 and 1,500 psi. This is the Hydroboost psi needed to apply enough brake line pressure and give good stopping power. Too low and the pedal gets hard. Too high and the system can blow seals.

Here’s a quick table for Ford truck brake pressure settings:

| Vehicle Type | Recommended PSI |

|---|---|

| Ford F-150 | 1,200 PSI |

| Ford F-250 Super Duty | 1,300 PSI |

| Ford F-350 Hydroboost | 1,500 PSI |

If you modify your system, always double-check the correct range. Matching pressure keeps your Hydraulic brake assist running smoothly.

Hydro-Boost System Bleeding & Fluid Maintenance

When changing fluid or replacing parts, air can get trapped inside. That’s why Hydroboost maintenance includes bleeding the system. Always bleed the Hydroboost system to avoid a spongy brake pedal or fluid aeration. Turn the wheel and pump the pedal to get rid of air bubbles.

Use only Brake fluid DOT 4 or the fluid your vehicle needs. Old or dirty fluid can damage the master cylinder, lines, or seals. Perform brake fluid replacement every 2–3 years, or if it looks dark or smells burnt.

Replacing or Upgrading Your Hydro-Boost System

If your Hydroboost system leaks or fails completely, replacement might be needed. Choose between OEM parts and brake system upgrades. Performance versions offer better brake response time and work well for trucks and off-road builds.

During installation, flush the fluid, bleed the system, and check for any deadhead pressure problems. Make sure the Hydroboost components and master cylinder are torqued properly. Upgraded pumps may also improve power if you’ve added bigger tires or tow trailers.

Common Errors – Brake Pads, Steering & Pressure Mismatches

Some users make mistakes when installing or upgrading. Using the wrong brake pads can change how the pedal feels. Soft pads combined with a strong booster can cause uneven stops. Also, mismatched pressure adjustment methods can lead to front brake bias problems or poor control.

Always pair the Hydroboost system with a matching power steering pump. Wrong sizes or incompatible setups can hurt performance or even damage parts. Don’t forget the role of the brake proportioning valve, especially after doing a brake caliper upgrade.

Hydro-Boost Power Assist Systems

Performance Tips and Modifications

Want better Hydroboost performance? Upgrade to high-output pumps or larger master cylinder setups. This gives stronger assist for off-road or racing. For even more control, try tuning the front brake bias using a valve. You can also install inline filters or coolers to keep the fluid clean and cool.

If you’ve already done a brake caliper upgrade, adjust pressure with a pressure gauge for brakes. Keep fluid fresh and check for leaks regularly. These steps keep your Hydraulic brake assist ready for anything.

Conclusion

The Hydroboost brake system is a top choice for drivers needing strong, dependable brakes. It beats the vacuum brake limitations found in older systems. By understanding how the Hydroboost components work and how to fix them, you can get the most from your Ford braking system.

Use quality parts, keep up with Hydroboost maintenance, and always match pressures. A little care now prevents big problems later. Whether you’re driving a Ford F-350 Hydroboost, building a 4×4, or towing heavy loads, this system gives the stopping power you need.

FAQS

What is the operating pressure for the HydroBoost?

A: It usually operates between 1,300 to 1,600 psi, depending on the vehicle.

Q: What supplies the power needed for brake assist on a diesel vehicle equipped with hydro boost system?

A: The power steering pump provides the pressure needed for brake assist.

Q: What is the pressure in the hydraulic brake system?

A: Most systems run at 1,000 to 2,000 psi during braking, depending on design and load.

Q: What are the symptoms of a bad Hydroboost brake booster?

A: You may notice a hard brake pedal, brake fade, fluid leaks, or poor braking power.